High muab tub lim yas parallel ntxaib ntsia hlau recycling thiab granulation kab tshuab

Lub ntsiab parameter

Ntsia hlau loader

● Nws phim nrog extruder pub hopper kom paub txog kev tswj tsis siv neeg.

Feeder

● Hopper khoom: Stainless hlau; Txoj kev pub mis: ntsia hlau pub; Feeder maub los: Tswj los ntawm inverter.

Extruder tshuab

● Cov ntsia hlau thiab lub tog raj kheej txais yuav "lub tsev thaiv" qauv, uas muaj kev sib hloov tau zoo thiab tuaj yeem siv rau hauv ib qho kev sib xyaw ua ke raws li cov khoom siv sib txawv; Lub tog raj kheej yog ua los ntawm nitrided steel thiab bimetallic cov ntaub ntawv, uas yog hnav-resistant thiab.

● Corrosion kuj thiab ncua kev pab cuam lub neej; Cov threaded Cheebtsam yog ua los ntawm nitrided steel thiab high-ceev cuab yeej steel, thiab cov curves yog tsim los ntawm computer-aided tsim, ua ke nrog cov txheej txheem ua tshwj xeeb, kom ntseeg tau tias cov hniav ib txwm ntawm threaded ua hauj lwm seem.

● Kev tshem tawm ntawm qhov chaw thiab kev tu tus kheej zoo; Txoj kev tsim tshwj xeeb tsim kev sib txuas thiab cov cuab yeej sib kis tau txhim kho lub zog ntawm cov khoom siv threaded thiab core shafts, ua tiav cov khoom sib txawv, kev sib xyaw zoo thiab cov nyhuv plasticization, thiab cov khoom siv hysteresis.

● Lub hom phiaj ntawm lub sij hawm tuav luv luv thiab siab conveying efficiency.

Screen hloov pauv

● Cov hloov pauv hloov pauv txawv raws li qhov xav tau ntawm cov neeg siv khoom sib txawv.

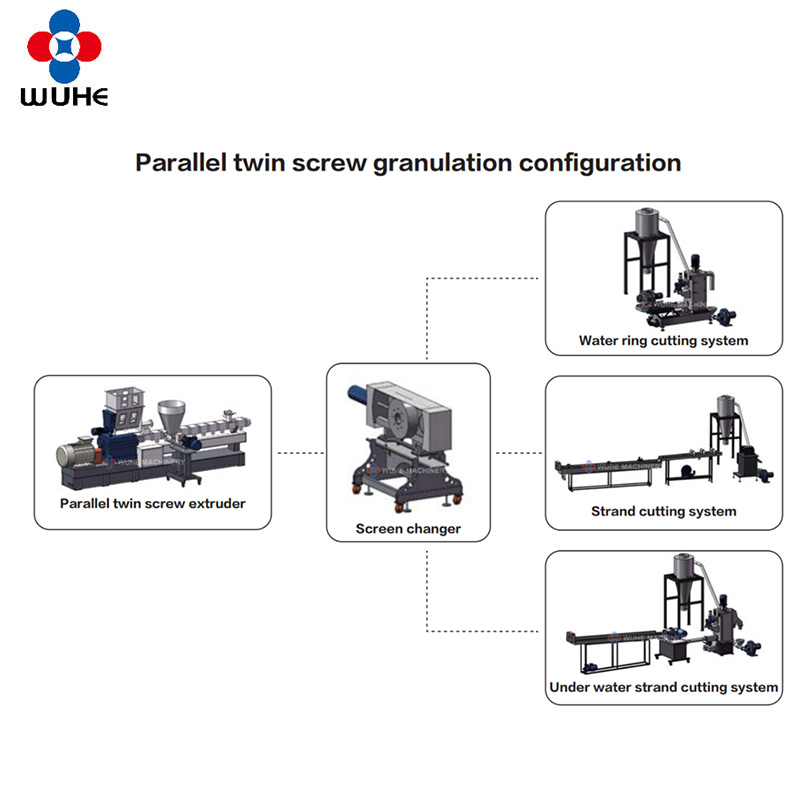

Peb feem ntau muaj peb hom pellets txiav system:

1. Lub nplhaib dej txiav qhov system.

2. Txoj hlua txiav qhov system.

3. Lub underwater strand txiav system.

Raws li cov yam ntxwv ntawm cov khoom sib txawv, peb yuav pom zoo txoj kev txiav sib txawv.

1. Dej nplhaib txiav qhov system

● Cov txheej txheem txiav tau txais cov extrusion tuag lub taub hau dej nplhaib los txiav, uas tuaj yeem ua kom pom qhov zoo tshaj plaws ntawm cov khoom.

Centrifugal dewatering tshuab

● Lub tshuab no muaj ntau yam zoo, xws li qib siab ntawm lub cev qhuav dej, kev siv hluav taws xob tsawg, kev ua haujlwm siab, qib siab ntawm automation, thiab txo kev siv zog ntau. Lub cev qhuav dej yog huv si, thiab nws tseem tuaj yeem ntxuav tawm cov xuab zeb thiab cov khoom me me hauv cov pla.

2. Strand txiav system

● Rau qee cov ntaub ntawv uas muaj viscosity siab, xws li PP, peb pom zoo kom siv ib txoj hlua txiav.

Underwater sawv ntsug txiav system

● Haum rau cov khoom siv melting siab, xws li PET thiab PP thiab lwm yam.

● Cua pipeline kom qhuav

Cov dej hauv pellets nto yog evaporated los ntawm cov raj xa dej xaim cua, thiab nws thauj cov pellets qhuav mus rau qhov sau hopper, tom qab ntawd rau kev kho mob.

Hluav taws xob tswj qhov system

● PLC tsis siv neeg tswj

Cov duab kos duab